Why Laminated Veneer Paper Being an Ideal Finishing Choice for Plywood?

With the increasingly diversified needs of consumers, the decorative materials in the market have also become diverse, such as melamine paper, veneer, HPL, etc. As one of them, laminated veneer paper is mainly used to make melamine plywood, and it is gradually occupying the dominant position of melamine plywood finishes.

Anyone in wood industry knows that the surface of plywood is rougher than MDF and particle board. Melamine paper can be directly pasted on MDF and particle board, but it cannot be applied to plywood.

Initially, the most widely used on plywood’s surface is veneer, such as ash. Although it has beautiful patterns and natural intimacy, the process of painting the veneer is time-consuming and labor-intensive. Moreover, the formaldehyde content in paint is high, and high-quality paint will increase the cost, so this drawback has been plaguing the industry.

The emergence of HPL solves this problem. HPL is melamine paper pasted on craft paper, which satisfies the desire of the plywood manufacturers to apply melamine paper on plywood. It can also avoid the trouble of painting, save paint, improve efficiency, and reduce the defects of uneven spray color. Until now, HPL still has market advantages.

Reducing cost input on the premise of ensuring quality is the long-term pursuit of enterprises. The advent of HPL has also inspired people to explore more. Finally, in 2012, the founder of our company developed laminated veneer paper which replaces the back of the HPL with recon veneer, greatly reduces the cost.

Using a cold press or a hot press, the LVP can be directly applied to the surface of the plywood, and various finishing effects, such as matte, high-gloss, etc., have been completed on the surface of it. So during the pressing process, there is no need to change various steel plate, which achieves time-saving and labor-saving.

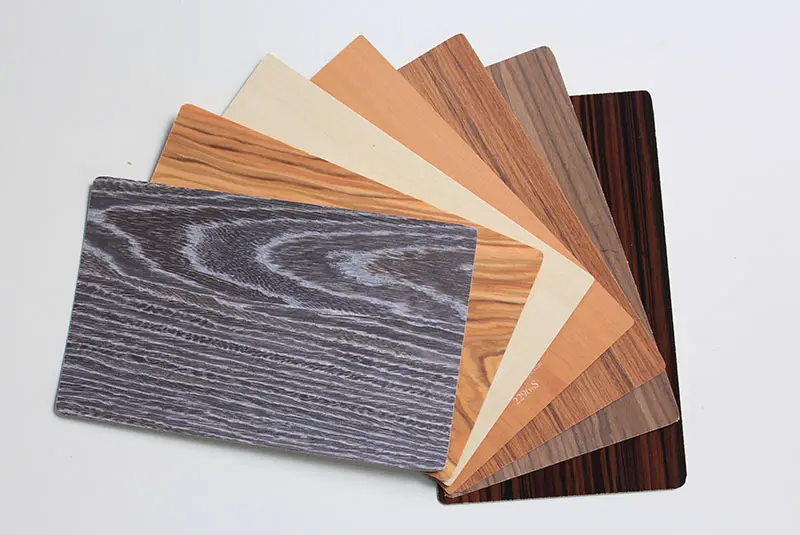

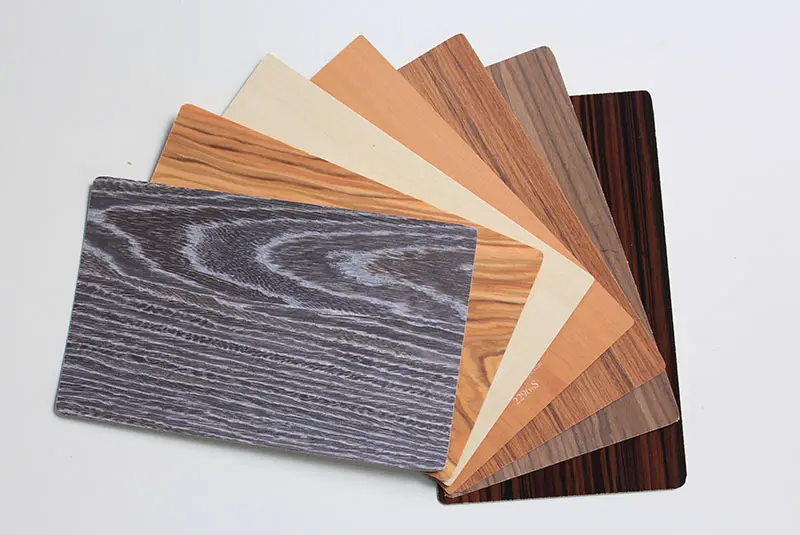

Compared with HPL, LVP has more available designs. Synchronized designs are more aesthetically pleasing than normal ones. In China's market, 70%-80% of LVP’s designs are from our company.

Customers' needs drive market changes. Whether low-end or high-end products, LVP can meet the needs of customers.

Conclusion

LVP itself not only serves plywood manufacturers, helping them reduce costs and increase profits; it also serves consumers, with diverse designs and continuous innovation to meet different needs.

From China to Dubai: A Dialogue Between Wood and the World

From China to Dubai: A Dialogue Between Wood and the World

Explore Innovation and New Synchronized Design at the 2025 Dubai International Exhibition!

Explore Innovation and New Synchronized Design at the 2025 Dubai International Exhibition!

The advantages of synchronized melamine panels

The advantages of synchronized melamine panels

New product: Melamine recon veneer plywood --- The new solutions for the plywood and block board decorative surface

New product: Melamine recon veneer plywood --- The new solutions for the plywood and block board decorative surface